-

- Industrial Grinding

-

Project DackgroundBauxite is a kind of high quality fireproof material, it can also be used for aluminum smelting, and i... MORE>>

- Aggregate

-

Project BackgroundIn Decmeber, 2016, we made a 200 t/h basalt crushing production line for a customer in India. The out... MORE>>

- Metallic Mineral

-

Project BackgroundThe process of copper beneficiation line is relatively simple. Raw materials are crushed before the gr... MORE>>

- Building Materials

-

Project BackgroundRiver pebble is a natural stone taken from tore which is formed by uplifted ancient river bed through ... MORE>>

-

- Industrial Grinding

-

In industrial grinding filed, General Mining Machinery grasps professional technologies throughout the entire process ch... MORE>>

- Aggregate

-

In aggregate filed, General Mining Machinery with professional crushing technologies for soft, medium hard and hard mate... MORE>>

- Metallic Mineral

-

In metallic mineral filed, General Mining Machinery can process soft, medium hard and hard minerals and provide various ... MORE>>

- Building Materials

-

In building material field, General Mining Machinery provides clients with professional resolution and complementary pro... MORE>>

- Home > SOLUTION > Industrial >

-

-

Industrial Grinding

-

Aggregate

-

Metallic Mineral

-

Building Materials

Talc

Product Introduction

Product Introduction

Talc is a common silicate mineral, and its hardness is 1-3 in Mohs. In paper making industry, talc is mainly used in paper making packing, coating, resin control and deinking agent. The talc has stronger fixation for pigment. Used in rubber, talc can increase the volume of the rubber, improve the rubber processability, take halfreinforcing or reinforcing effect and adjust the hardness of rubber. Used in plastics, talc can increase the volume of the plastics, reduce product cost, improve the dimensional stability, hardness and rigidity of plastics and improve the heat resistance and astigmatism of plastics.

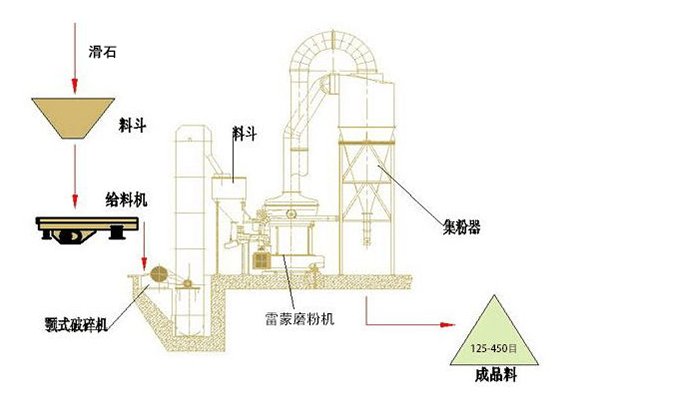

Technical Process

Technical Process

Firstly, massive talc material is crushed into the feeding size (15mm-40mm) which can enter the mill by crusher. In first crushing, small materials that meet grinding condition are transported to grinding chamber of the grinder uniformly and quantitatively by feeding system. Then they are ground to powder in grinding chamber. After grinding, the materials are graded by powder concentrator with system airflow. After grading, the unqualified powders will return to the chamber of the main engine for regrinding. The powders which meet the fineness are piped into powder collecting system with airflow. The air and the powders separate and finished powders are sent to finished products stock bin by conveyor device. Then they are packed by powder tank or automatic packing machine together.

Equipment Selection

Equipment Selection

|

Fineness |

Application

|

Equipment |

|

Below 200 mesh

|

Used for making various fodder

|

Raymond Grinder, High Pressure Grinde

|

|

200-325 mesh |

Well drilling, paper making,etc

|

European Mill, Raymond Grinder |

|

Above 325 mesh

|

High-end chemical additive, high end paper

|

High Pressure Grinder, European Mill, Raymond Grinder

|

Raymond Grinder High Pressure Grinder European Mill

Almost 15 years service experience and thousands of user's requirement

make General Mining Machinery know well about your concern and requirement and offer you more specific resolution.

Cellphone

Cellphone

WeChat

WeChat